April 8, 2022

Improving Machining With 3D Printed Tools

The machining of powertrain components and aluminum prismatic parts, such as stator housings for the growing electric vehicle market, often require large and heavy tools. When used on traditional machining equipment, the weight of these tools can cause excessive spindle vibration and chatter, poor tool life and, potentially, scrapped components.

Lightweight Solution: Additive manufactured tools can be a good solution for companies looking to reduce the weight of the tool – and thus wear and tear on the spindle. With 3D printing, there is about a 30% reduction in tool weight, yet it has the equivalent torsional stiffness of a steel ground body tool. Lightweighting can play a big role in large, heavy tools that take a toll on the machine spindle, helping to reduce preventative maintenance. These improvements can be significant when producing aerospace and automotive components, including electric vehicle parts, where existing spindle interfaces are not always ideal for some of the size/weight of tools

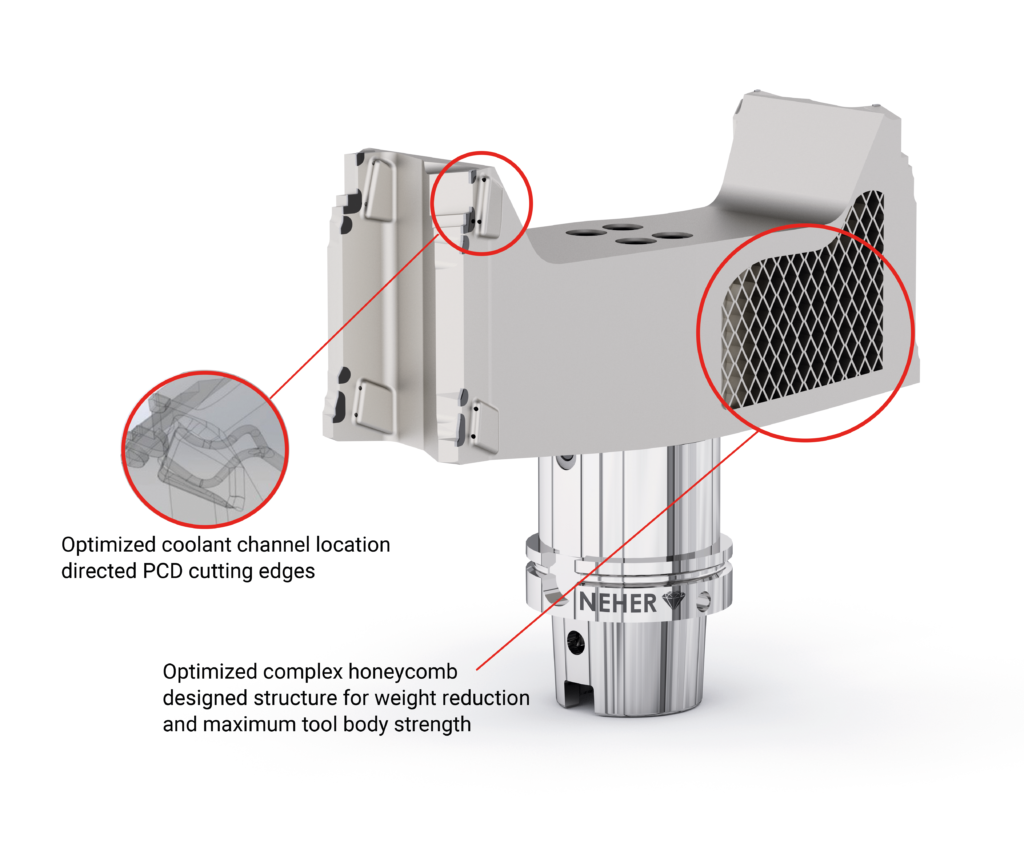

Optimized Coolant Channels: Another key benefit of this technology is its ability to produce geometries that cannot be achieved conventionally. The freedom enabled by 3D printing technology enables strategic placement of the coolant channels, optimizing the coolant exit location by aiming directly at the cutting edges, whereas in traditional tooling these holes are drilled into the monoblock body.

This ability to optimize coolant hole and cooling channel locations and improve tool damping, can improve tool life by 30% or more and is well suited to the growing, and environmentally-friendly, MQL (minimum quantity lubrication) trend. Simple geometries based on the model of nature (bionics) can also be integrated into tools.

Eco-Friendly: Another major benefit of additive manufacturing lies in the energy efficiency of the 3D printer — this is significant and should not be overlooked. With a power consumption of approx. 4.6 kVA, the 3D printer electricity usage is drastically smaller than a milling machine with 60-70 kVA. If the turning and milling process is replaced by the printer, around 90% of the energy can be saved.

Star Cutter and technology partner Neher have partnered to provide 3D printed PCD monoblock tool bodies and chip deflectors to customers. The 3D printed bodies are integrated with the holder interface to create a single robust tool that can improve machining operations, especially on large components.

Interested readers can download our 3D Printed brochure to find out more.