Recent Blog Posts

Tooling for Rifle Barrel Manufacturing

Options for Improving the Machining of Upper Rail Systems

Achieving perfect concentricity with the SRT Reamer

All Star SU Blog Posts

Tooling for Rifle Barrel Manufacturing

A rifle barrel typically begins life as a cylindrical steel bar. The transition from steel bar to a full-fledged rifle barrel begins with a deep-hole drilling process as the initial step, where a long drill with a hollow stem and tungsten-carbide bit is used to drill the trued and stress-relieved bar. To achieve the proper […]

Read Full PostOptions for Improving the Machining of Upper Rail Systems

The rifle upper rail system allows the attachment of various accessories such as scopes, sights, and flashlights. Mounted on the top of the rifle, it needs to provide a stable platform for the accessories to be attached to, yet not add more weight than needed to the rifle. As such, many firearm manufacturers look to […]

Read Full PostAchieving perfect concentricity with the SRT Reamer

The SRT, or Super Round Tool, is a patented reamer designed by the Northern Tool division of Star Cutter Company to create the best quality reamed hole across a spectrum of applications. The SRT combines two tools into one – it offers multiple straight flutes for consistent location and multiple helical flutes that ensure roundness […]

Read Full PostImproving Machining With 3D Printed Tools

The machining of powertrain components and aluminum prismatic parts, such as stator housings for the growing electric vehicle market, often require large and heavy tools. When used on traditional machining equipment, the weight of these tools can cause excessive spindle vibration and chatter, poor tool life and, potentially, scrapped components. Lightweight Solution: Additive manufactured tools […]

Read Full PostThe benefits of re-tipping and re-cutting PCD tooling – Updated

Fixed Pocket PCD milling and interpolating tools are designed and built as a complete one piece product, combining a steel body and a holding interface. Additionally, PCD segments are brazed into the tool body. The PCD segments then go through the manufacturing process to meet the requirements of the finish tool geometries. This type of product is known in […]

Read Full PostHow using Near Net Shape Carbide Blanks can save you time!

One goal of the H.B. Advantage is to save our customers time when machining our blanks. By providing near net shape blanks, we can reduce the overall grinding time required to finish the blanks. We do this by adding features such as diameters, flutes, pockets, flats, coolant holes, etc. All machining is done in the […]

Read Full PostImproving the Upper Machining Process with the SRT Reamer

Star SU is currently involved in process improvement for machining the Upper Rail system for AR-15’s, AR-10’s and M-4 carbines with several independently owned contractors. Process improvement includes: Concentricity improvement (TIR) critical to non-critical bore Cycle Time Reduction Surface finishes of Ra ≤ 0.8 Typical current process: Rough Drill Ream non-critical bore End mill critical […]

Read Full PostImproving the Process of Machining the Firing Pin Hole with the Solid Carbide Twist Drill

With the industries increased volumes, there is a need to reduce cycle times in machining the firing pin hole in gun bolts. This is what the Star SU process is looking to improve upon compared to the traditional process. The traditional process is outlined below: Pilot Tool Single Flute Gundrill Solid Carbide Internal Chamfer Gundrill […]

Read Full PostThe NXT generation of tool grinding has arrived

Elk Rapids Engineering a division of the Star Cutter Company and manufacturer of the Star brand of CNC tool and cutter grinders has been hard at work designing, testing, and refining their next generation (5) axis machine. Similar to Colonel Steve Austin in the science fiction movie Six Million Dollar Man, Engineers at Elk Rapids […]

Read Full PostGear Solutions – April Issue: Star SU Company Profile

In today’s competitive gear manufacturing market, to be considered local — whether that’s North America, Europe, or China — is a good way to get left behind. That’s why Star SU LLC has gone to great lengths over the years to expand its presence on a global scale, offering its machines, cutting tools, and services […]

Read Full PostIn depth: The Barrel Reaming Process

Rifle barrels are made a number of ways, but the most common method starts with a gundrill, followed by reaming, and finally rifling with a button. Other popular methods would include hammer forge, honing, or cut rifling. No matter the method, drilling a deep hole is necessary. Star SU reamers, drills, and buttons focus on […]

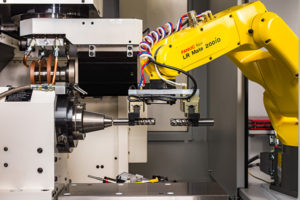

Read Full PostIn-depth: NTG-6RL Robot Loading System

The NTG – 6RL CNC tool and cutter grinder uses a Fanuc 200iD robotic loader with a custom gripper system designed by Star. The robot can change part blanks ranging from 3-32mm in diameter in various workplace lengths, all with the same set of gripper fingers. There is no requirement to change inserts, no re-alignment […]

Read Full Post