December 14, 2023

Tooling for Rifle Barrel Manufacturing

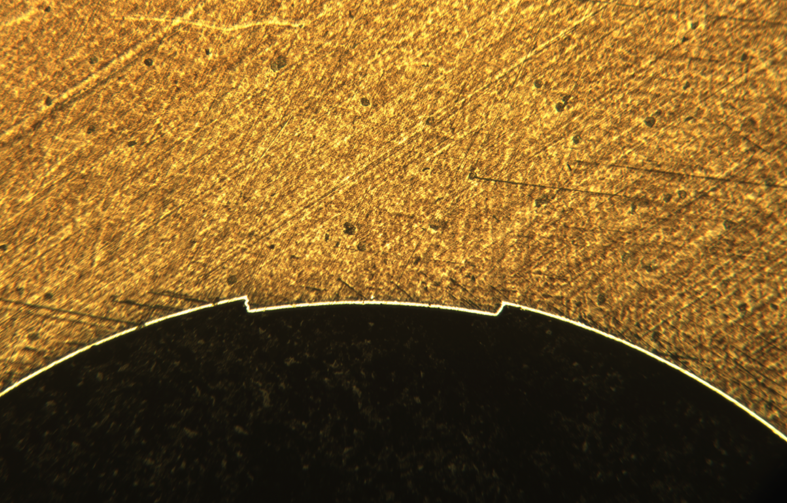

A rifle barrel typically begins life as a cylindrical steel bar. The transition from steel bar to a full-fledged rifle barrel begins with a deep-hole drilling process as the initial step, where a long drill with a hollow stem and tungsten-carbide bit is used to drill the trued and stress-relieved bar. To achieve the proper diameter and surface finish, the drilled hole is then reamed carefully to avoid leaving any marks on the bore surface. Common defects include reamer marks caused by dull or improper use of the reamer. Once the hole is straight and uniform in size, rifling grooves are added through cut, broach, or button rifling methods.

Star Cutter Company manufactures tools for producing rifle barrels including gundrills, push and pull reamers, and rifle buttons that provides quality in every geometrical detail with exceptional part finishes.

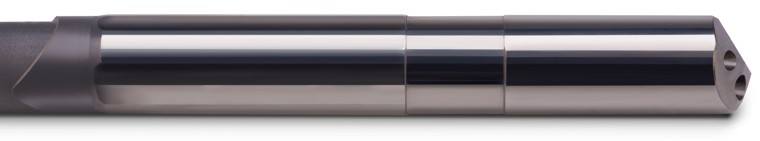

It Starts with the Gundrills

Star Cutter offers a full line of single flute gundrills to machine all types of materials, including 4140 and 4150V steel and 416r series stainless steel.

Our experience has allowed us to perfect our manufacturing standards processes so that our tools provide superior performance that meets or exceeds our customers’ expectations. Understanding that companies are always under demanding delivery dates, Star offers very competitive lead times through our Gundrill Express program for smaller order quantities, allowing tools to be shipped one week after receipt of order.

Our gundrills for barrel manufacturing include options for special advanced coatings, double contour, and high performance gundrills. All these enhancements are also available through our express program, with an adjusted lead time.

Designs for Better Process Control

Star Cutter Company has perfected a custom design utilizing an extended length carbide head with double contour geometry. This special tool design has proven to reduce the tool drift for the depth of cut. This results in excellent TIR readings from entry to the exit of the part. This is accomplished by combining our special contours and an additional rear piloting contour configuration that performs like extra guide pads, forcing the tool on location. Once in the cut, these guide pads continue to force the tool to cut a straight path for the remainder of cut. This special design can also assist in controlling hole size where in some cases you can eliminate your reaming operation.

Solutions for High Speed Drilling

While traditional gundrilling has historically proven to be effective, Star Cutter also offers high performance gundrills, which can run 3-4x faster than a standard gundrill. This unique design has a special ground rake to effectively control the cutting chip when executed under optimum machining conditions forming a chip formation that resembles the number “6”. This will prevent larger chips in the evacuation stream down the flute to avoid catastrophic failure.

|

|

|

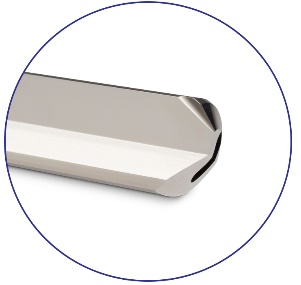

Push and Pull Reamers for the Next Step

Star Cutter has perfected a full range of barrel reamers covering 17-50 calibers. Each reamer is specifically designed – including 4 – 6 flutes – depending upon the application. Our designs have proven to provide excellent controlled finishes that are ideal for your button applications. Special trouble shooting designs are also available to assist with bore entry and/or exit hole size controls. We also offer a full range of special coatings for optimization of the process pending the materials being machined. These reamers can be purchased with or without the rod.

Get in the Groove with Rifle Buttons

Next step is the cold forming of the rifling grooves and resizing the bore in gun barrel. Star Cutter manufactures buttons to your specifications, or we can verify the size of the button based on material, hardness and wall thickness of the blank. Our button range covers 17-50 caliber sizes that include the proper twist your part requires. We apply advance coatings with a high polish for all our buttons to maximize the performance results and accuracy from button to button. Our buttons are available with or without the rod.

Jamie Dunneback

Product Sales Manager – Round Tool Divisions