HIGH-PRECISION MEDICAL APPLICATIONS

Given the stringent requirements within the medical industry, companies need an optimal tooling solution that best meets their machining application. Star Cutter is recognized for design and build tooling solutions that solve unique challenges while helping to reduce time, improve quality, and achieve cost savings. We analyze your process, materials, equipment, and requirements to provide a solution that optimizes your particular medical machining challenge.

We offer precision tooling for precision instruments and orthopedic cutting tools; femoral nail and intramedullary interlocking nails; cannulated bone screws and general parts.

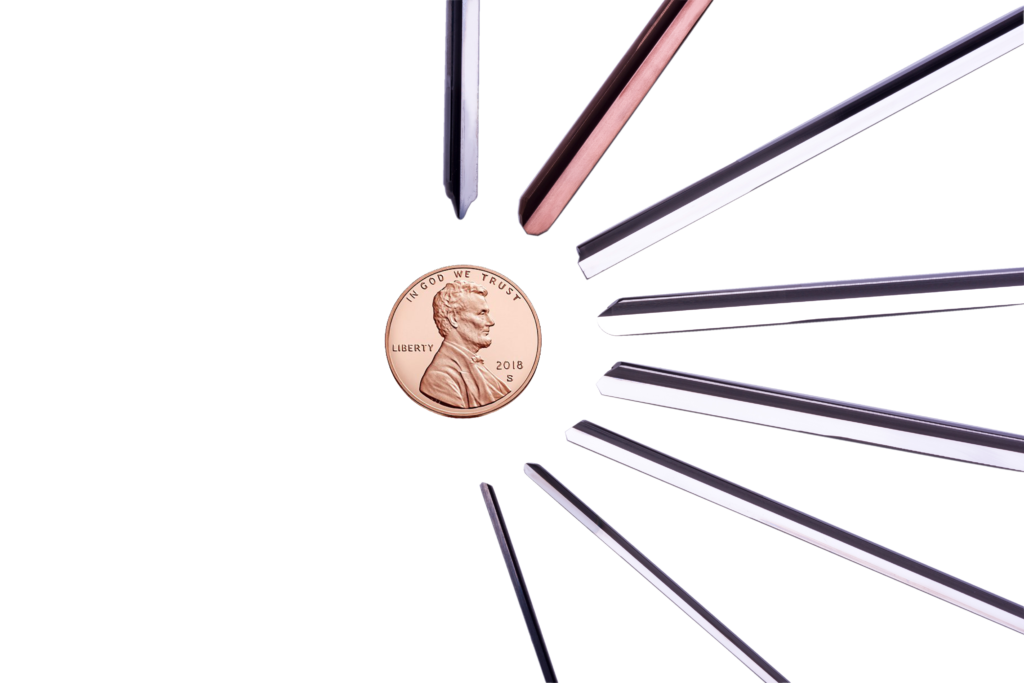

Small Diameter Solid Carbide Gundrills

- Application specific design with optimized point geometries, polishes, hones, etc.

- Material-specific carbide grades and coatings

- Diameter range from 0.700 mm – 5.00 mm or greater, if needed

- Coolant-fed

- Better tool life and performance compared to off-the-shelf solutions

Solid Carbide Small Diameter Combination Tools

- Reduce cycle time and lower CPU by combining operations

- Overall tool cost reduction (fewer tools)

- Improve part quality (concentricity between features)

- Multiple-feature tooling; combine diameters, counterbores and chamfers

- Coolant-fed: >0.900 mm diameter range

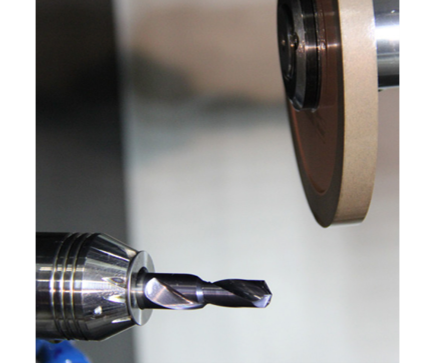

Small Diameter Deep Hole Solid Carbide Twist Drills

- Application specific design with optimized point geometries, polishes, hones, etc.

- Custom lengths up to 50 x Ø.

- Diameter range starts at 0.900 mm

- Material-specific carbide grades and coatings

- Coolant-fed

- Better tool life and performance compared to off-the-shelf solutions

Single Flute Gundrills

- Diameter range from 2.40mm - 38.1mm

- Competitive lead-time with many in-stock sizes and lengths

- 72-hour special delivery custom stock available

Round Tool Reconditioning Services

In addition to optimized tooling, Star’s tool services can help keep your tools running efficiently with individualized round tool reconditioning and resharpening support services. We use state-of-the-art technology to restore all types of tools including deep hole drills, special carbide drills and reamers - including cavity port tooling and fixed pocket PCD tooling to their original sharpened quality, condition, and performance. Advanced recoating services are also available to improve tool performance after sharpening.

Case Studies

Single Flute Gundrill

| Application | Bone Reamer |

| Material | Stainless Steel 400 |

| Drill Size | 1.397mm ø |

| Select Tool Features | Polished carbide, select grade and coating, honed edges |

| Feed Rate | Increased from 38.1 mm/min to 63 mm/min |

| Throughput | Increased from 21.7 to 31.5 parts/hour |

| Tool Life | 110 parts/use to 220 parts/use |

| Cost Savings | $18,900 |

Solid Carbide Gundrill

| Application | Canulated Bone Screws |

| Material | Titanium 6AL-4V |

| Drill Size | 1.727mm ø |

| Select Tool Features | Polished carbide, select grade and coating, specific geometry and hones |

| Feed Rate | 25.4 mm/min |

| Throughput | Increased from 21.7 to 31.5 parts/hour |

| Tool Life | 750 parts/use to

1,750 parts/use |

Solid Carbide Gundrill

| Application | Orthopedic Instrument |

| Material | Stainless Steel 400, 17-5 and H900 |

| Drill Size | 1.600 mm ø |

| Select Tool Features | Polished carbide, select grade, honed edges and coating |

| Feed Rate | 45 mm/min |

| Tool Life | Doubled |

Single Flute Gundrill

| Application | Femoral Nails |

| Material | Stainless Steel 400 |

| Drill Size | 5.334 mm ø |

| Drill Depth Range | 300 – 500 mm |

| Select Tool Features | Select carbide grade with excellent surface finish on tool head |

| Feed Rate | 25mm/min |

| Throughput | Increased from 31 – 40 parts |

Small-Diameter Deep Hole Solid Carbide Twist Drill

| Application | Orthopedic Device |

| Material | Titanium 6A-14V |

| Drill Size | 4.35 - 4.55mm ø |

| Select Tool Features | Select carbide grade; sculptured flute opening for enhanced chip control; polished surface finish on critical areas of tool |

| Hardness | 35-38 Rc |

| Result | 4 linear meters of cut until tool change |

Solid Carbide Small Diameter Combination Drill

| Application | Orthopedic Parts |

| Material | Titanium 6A-14V |

| Drill Size | 1.600 mm ø |

| Select Tool Features | Combined multiple diameters and transition features into a single tool |

| Result | Saved 5 minutes in cycle time with development of combination tools |

| Cost Savings | $250,000 |